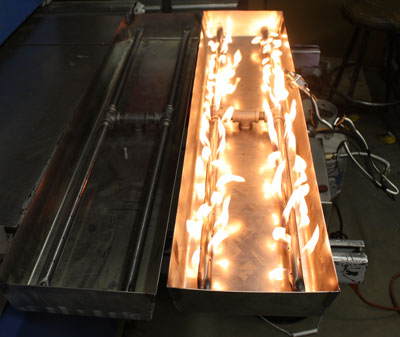

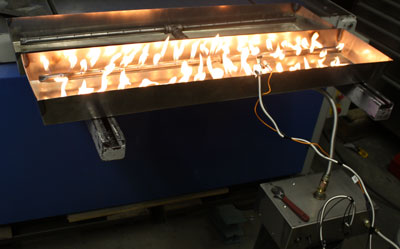

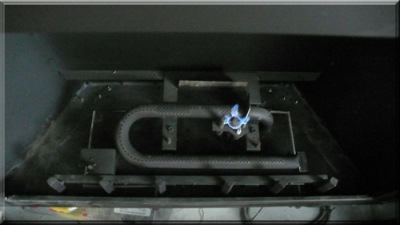

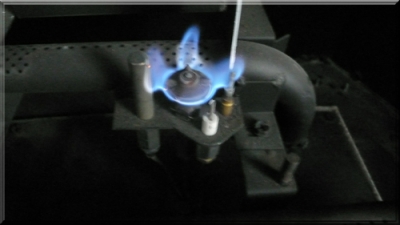

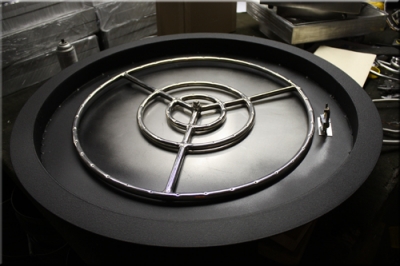

The ventless burner below is made of steel and there were actually 4 of these made. We covered the front and sides with 5" skirts. There are being installed in Georgia and as soon as they send pictures we will post them These pictures were taken just after the testing. This is a propane ventless burner and these are available in natural gas as well.

The pictures below are of the same burner as above with Azurlite Base Glass installed. These 4 ventless burners are being installed in Georgia.

The skirts will hide the the valves and the remote control will be moved to the side of the fireplace. This was a ventless burner the customer sent to us for conversion and they asked for us to add a remote to all 4 ventless burners.

The fireplace below is in Glendale Hills California. We installed Starfire Base Glass as a base with about 1 lb of Ice Ice Ice Topper on top. Then to finish it off we installed a brass surround with bronze frosted glass. The customer loved it! She is the CEO of Fredrick's of Hollywood! Awesome house by the way.

The two pans below are stainless steel and are propane fueled with 415,000 btu electronic ignitions each.

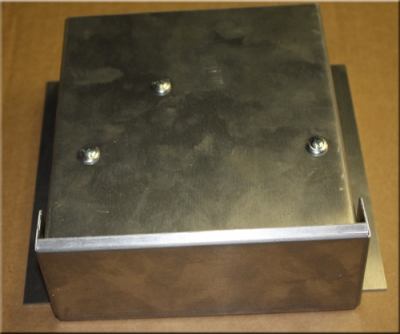

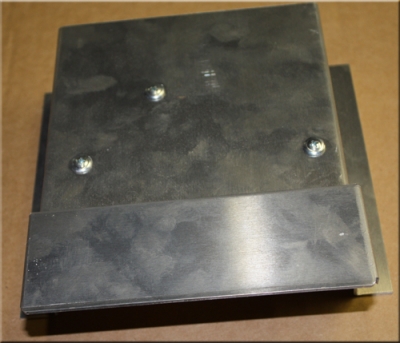

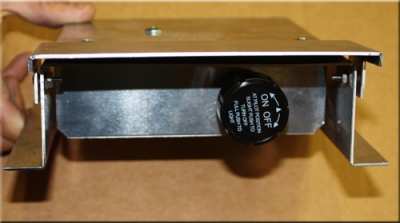

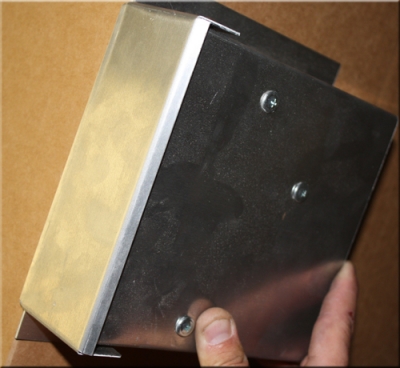

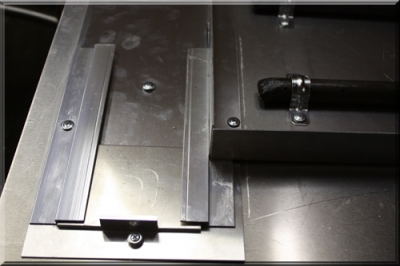

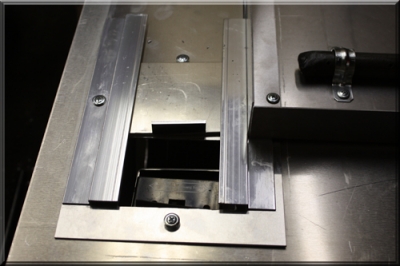

The next several pictures show you a flip top box design for a fire pit control panel. It is constructed from stainless steel or could be made from aluminum. The trimming valves are for adjusting the flame are inside along with an electronic key to activate the electronic ignition. These were made for an apartment complex and only the management had control of the electronic ignition. Here are the pictures.

These two separate boxes were made to fit each specific fire pit.

If you are building a fire pit or fire table and did not plan for and where your controls will be located, we have a solution! We can build a Flip Top Box to conceal your controls for propane or natural gas. Here are 8 pictures for your possible project. We can modify these is dozens of ways to fit your fire pit project.

This is just the Copreci Valve and Air Mixer installed in the box. We can build a box to hold the FPPK with auto start as well.

The fireplace below is an outdoor fireplace fueled with propane. The remote control (battery operated) is located below by an access panel. We will explain as we move on. This fireplace and Propane Burner was installed in Florida.

Here is the fireplace the flat plate was installed onto.

Propane Burner before the glass.

On the left side notice the access panel for the battery operated remote control.

The entire cover is removed for access to the actual remote control.

This is a pilot light and thermocouple system and capable of and up to 100,000 btu's. The entire plate will be covered with glass when it is finished.

The next fireplace was installed by Ken Kenoyer. He constructed his own pan for his Direct Vent Fireplace conversion with our supervision. We will go through the steps to complete his installation. The glass that was used was Starfire Base Glass FireGlass and topped with Cherry Red Topping and Roma Red Topper. We will explain as we move forward.

Above is your fireplace now (if you like logs).

Below is your burner system that came with your wonderful Direct Vent Fireplace and logs.

Below is a pictures of your pilot light system

Below we have removed the "stuff" and exposed the pilot and gas connection.

Royce built a pan to fit the fireplace.

Below he cut the pan out to accept the pilot light.

Connected the gas line.

Tested the burner.

Pour the glass and your done! If anyone has told you that you can't convert a direct vent fireplace then these pictures and project don't exist! Just because they don't know what or how to do it, doesn't mean it can't be done.

The glass face is back on and it looks much better. A very nice and simple Self Installation!

Below is the surround of Torie Weiston Check out the other surrounds on the Fireplace Surrounds page!

The next fireplace is from Ash Sarna, one great room and beautiful view!

Check out other surrounds on the Fireplace Surrounds page!

The next pan (pans burners and baskets) is a ventless conversion. We cut the pan with a 1/2" front and a 2" back. We bent the front to be removable but also hide the controls. We Build to your needs and imagination! Be sure to see our Metal Page!

We are proud to announce that we have added a full sheet metal and welding facility to our company. If you have browsed the pages on our web site you can see the innovation our customers have allowed us to perform for the projects we have created. We are not just another company we are the innovative leaders. We never say NO! We can do anything for anyone anytime any where! We do work in all metals in any size, shape or form. We also have been known for some of the most creative burner systems in the fireplace and fire pit industry. We will be posting pictures to this page in the next few weeks, so please ask and come back from time to time.

Ed

Here is our first project in our metal shop. A portable fire pit for propane or natural gas. These will be available in unfinished (as shown) just add your stone, plaster, marble, granite, brushed stainless steel or? The fire pit shown is a natural gas with Multi Mix Base Glass (about 30 to 40 colors from our mixing counter. The size is a 30" x 30" x 12" tall. The custom fire pits we will be manufacturing have a single wall construction frame with a drop in solid bottom fire pan/ tray. We will be offering both versions.

Here are several shots of some different variations of our RV Fire Pits. The come in standard sizes of 14", 16", 18" and 24".

In stainless steel or steel painted in a choice of 25 colors!

They are also being made available is a 20" round pan in stainless, steel painted or aluminum!

The square pans can have special lids/ covers made that are 3" to 6" tall which can be used as a base to set the fire pit on if you don't want it setting on the ground. We will post pictures of these in a few weeks or as soon as we can, time permitting. The pictures that were taken were with the company Motor Home (Tiffen Pheaton Bus)(one of a kind). The RV Fire Pits were developed for us to take camping. Necessity is the mother of invention!

Above and below is our 24" stainless steel RV Fire Pit with Azurlite Base Glass.

Above we are burning at 80,000 btu's

Below we are burning at 100,000 btu's

All of the RV Fire Pits we build we build with 100,000 btu capability but we recommend not to burn that high.

These are sitting on the typical plastic carpets used for motor homes and the bottoms don't get hot enough to melt the carpet.

We recommend using a portable 20 lb tank but you can tap into your coaches supply if you would like. We always take at least 2 extra tanks along so we don't have to drain the coaches supply.

Quick disconnect hoses come in 10'. 12' and even 15' lengths. You can even attach them together.

All through out the pictures you can see the propane tank close to the RV Fire Pit. We did this intentionally. You can use as long of a quick disconnect hose as you would like. We also stock this in all sizes.

Below you can see it is easy storage.

Below you can see our 18" steel RV Fire Pit.

Above and below is our 24" stainless steel RV Fire Pit.

Below David is putting the 18" pit away. With glass the 18" pit weighs about 35 lbs.

The advantages with these RV Fire Pits is that you don't have your coach or trailer filled with smoke any more! You can sit right outside of your door under your cover of your coach or trailer. One tremendous advantage we found is that when you are under any cover by at least 5' to 6' you create an inversion and you actually deflect the rising heat to travel sideways. No more smoke, soot or even ashes to clean up, ever! These are considered recreational fires by any state fire code and are not considered open flames. Just the same a s a propane BBQ. Now you can have your cake and eat it too!

We will post more pictures or the next generation RV Fire Pits as soon as they become available! RV Fire Pit page

The propane pan below has a brushed finish on the front metal shield. This is a two part shield, one to retain the fireplace glass and second to conceal the controls. This is part of the fireplace design that was asked for. The first pictures shows the front completely up.

The picture below shows the complete front dropped down to access the controls.

Below we built 2 = 48" x 8" aluminum pans 4" deep with stainless steel burners installed. The were installed in the corner wall construction in the back yard at Lake Havasu Arizona. We will post the glassel pictures when the customer sends them to us.

The next table was built for a customer in La Jolla California. The table was 30" x 60" with a 24" x 54" fire pit area. They are going to make their own granite top to overlay.

All metal construction and their granite cut and installed.

The next pan burner is a propane pan burner with Skytech Controls. This unit has a standing pilot light with a remote control. To conceal the controls we manufactured a removable lift off front plate.

The next pan was built to the customers specs (round with 3" lip) and wrinkle finish powder coated.

Propane as well.

Note the thermocouple, pilot light and Copreci valve. We calibrate every burner to burn clean.

The next fire table was built by Brian Johnson of Omaha Nebraska, very nice! We supplied the components and Brian did the hard part, the table.

The blue is actually food coloring.

The next fire and water feature is one of our newer designs. The base bowl is a 24" spun aluminum bowl and the fire bowl is a 16" spun aluminum bowl. We will show you how it is made and tested.

The next fire pits were designed and built for the Marriott (Islandia previously) in Mission Bay California.

We started with several cardboard mock up tables for the hotel to approve.

We will explain as we move forward.

The hotel decided on the granite and we cut the granite with water jet and polished the edges.

These were installed on the private patios of the hotel suites.

Valves and location are important as well.

They ended up using a thermocouple and pilot light system with a battery operated igniter.

The next

The next pan is a stainless steel pan we manufactures for our customer in Hawaii. The system that was install was a

ventless burner to burn

propane with our glass. We will explain as we go forward.

On the front of the pan we we bend an open back hemmed stainless steel curtain to conceal the controls but it is still easy access.

This is the ODS (Oxygen Depletion Sensor) it speaks for its self.

Here we are burning propane with a

Starfire Base Glass, please note what a clean burn! We do it right.

All of our pans are built for each application and fireplace.

The next fire pit was built for Chuck Krallman in the Bahamas. The challenge was 15 knots per hour trade winds and propane. Not a problem. We mock up all of our projects to insure that they work properly. I will explain as we move on.

We first start testing the venting and use cardboard or plywood only later to be replaces with 1/2" glass panels.

Proper venting and maintaining an upward draft is very important.

Hopefully Chuck will send us the finished and installed pictures of the feature installed in his table.

Super "8" Stainless Steel Pans! Custom made just for you, check it out!

The next few pictures are from Steve Clendenen in Florida. Propane fireplace (burner pan next). He started with a basic cardboard mock up (very important) to get a preview. Here we go from start to end. we will later post the fireplace completed with the propane burner and glass installed.

Yuk, yuk and YUK!

I didn't particularly like the cardboard. we use full size sheets, but I guess it worked.

Notice the corner post is missing? There are a few rules to remove these.

Do you see the difference? We create nice and wonderful looking fireplaces for you (and the world). We really enjoy building these custom fireplace surrounds.

Click on the picture above or "HERE" to see the before and after pictures. Corten Steel Propane Fire Table.